Indiana’s Glassmaking History

- 1892 - A glass manufacturing plant is established in Indiana, Pennsylvania, on what later became known as Glass Avenue. The facility produces pressed glass items such as tableware and lighting components, benefiting from railroad access and regional fuel supplies

- 1896 - The plant is acquired by Harry Northwood, a prominent British-born glassmaker known for technical innovation.

- 1899 - The Indiana glassworks becomes part of the National Glass Company, a large glass manufacturing combine. Operations focus on standard pressed glass; creative development is limited under corporate consolidation.

- 1904 - Thomas E. Dugan, cousin of Harry Northwood and an experienced glass manufacturer, purchases the plant and forms the Dugan Glass Company. The factory enters a period of artistic and technical growth.

- 1905–11 - The Dugan Glass Company produces early carnival glass, applying iridescent metallic sprays to pressed glass forms. Popular patterns and colors are introduced; some pieces are marked with a capital D inside a diamond. The Indiana plant becomes an important contributor to early American carnival glass.

- 1912 - A major fire damages part of the plant, destroying molds and inventory. Although production resumes, the loss affects long-term output and financial stability.

- 1913 - Dugan sells the operation, which is reorganized as the Diamond Glassware Company. Diamond continues Carnival glass production, frequently using Dugan molds and adding new designs.

- 1913–25 - The Indiana glassworks remains active during the peak and subsequent decline of carnival glass popularity. Production gradually decreases as consumer tastes shift and inexpensive glassware falls out of favor.

- Late 1920s - The plant operates at reduced capacity amid economic downturns and declining demand for pressed and carnival glass.

- 1931 - A second catastrophic fire destroys most of the remaining factory structures. The damage proves economically insurmountable, and glass manufacturing in Indiana, Pennsylvania, permanently ends.

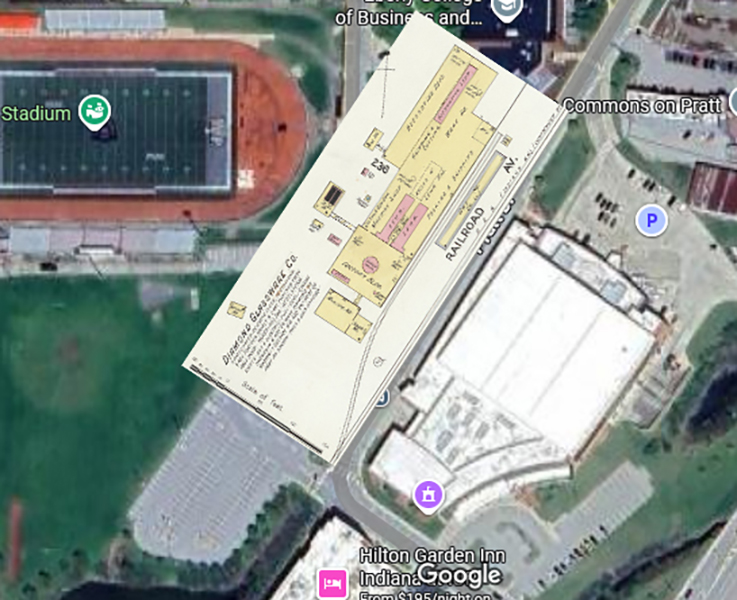

- post-1931 - The property is eventually sold and becomes part of what is now Indiana University of Pennsylvania (IUP).

A Brief History of Carnival Glass

Carnival glass is a distinctive type of iridescent molded or pressed glassware that emerged in the early twentieth century. Its surface shimmer—produced by applying metallic salts to hot glass—was intended to emulate the luxurious appearance of hand-blown iridescent glass from high-end makers such as Tiffany and Steuben, but at a fraction of the cost. Early examples were initially marketed under names like Iridill, aurora glass, and rainbow glass. However, by the 1950s, collectors had adopted the term “carnival glass” because many pieces were distributed as prizes at carnivals, fairs, and community events.

The first commercially successful carnival glass was produced beginning in 1908 by the Fenton Art Glass Company, founded in 1905. Fenton’s introduction of Iridill helped stimulate widespread production of iridescent pressed glass across the United States. Over the next two decades, a broad array of factories produced carnival glass in numerous patterns and colors—marigold being the most common—until demand declined in the late 1920s and production tapered off after 1931.

Although predominantly manufactured before 1925, carnival glass experienced a revival in the 1970s and beyond, with both historic companies and new producers issuing modern iridescent pressed glass that appealed to collectors and general consumers alike.

Today, carnival glass remains highly collectible, with both classic early twentieth-century production and later revival pieces sought after by enthusiasts. Early examples from Dugan and Diamond, including those made in Indiana, Pennsylvania, are prized for their historical significance and variety of patterns.

Indiana’s Contribution to Carnival Glass

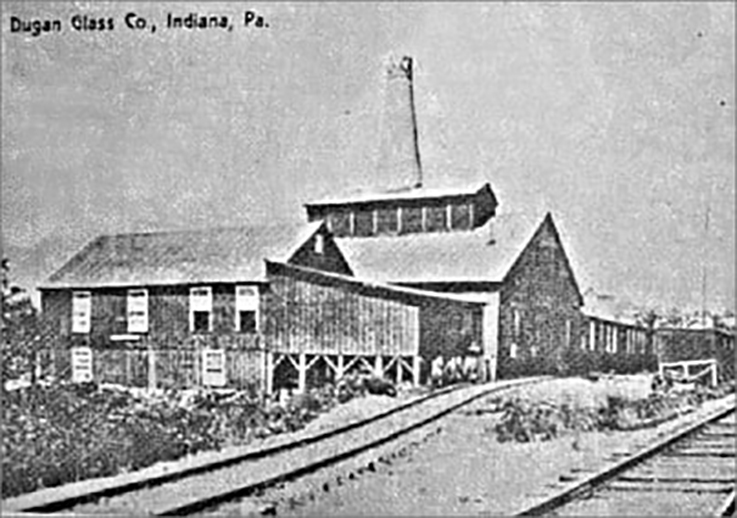

Glass production in Indiana began in the late nineteenth century. In 1892, an enterprise known as the Indiana Glass Company established a glassworks on what became Glass Avenue in the borough. Initially, this factory produced tableware, lighting components, and other pressed glass items, taking advantage of local transportation links such as the railroad.

The plant soon changed hands: in 1896, the facility was acquired by Harry Northwood, a British-born glassmaker. Northwood operated the works until 1899, when the factory became part of the National Glass Company combine. During the National Glass period, there is little evidence of carnival glass production, although the facility remained active in pressing glass goods.

In 1904, Thomas E. Dugan—an experienced glassmaker and cousin of Harry Northwood—purchased the plant with backing from investors, establishing the Dugan Glass Company. Dugan had long experimented with iridescent finishes and, by 1905, carnival glass bearing an iridescent sheen was being produced at the Indiana plant. The company’s output included a variety of pressed patterns finished in metallic iridescence that echoed the broader American trend and competed with other makers. Some pieces were marked with Dugan’s trademark of a capital D inside a diamond shape.

In 1913, ownership again shifted when Dugan sold the facility, and it became the Diamond Glassware Company. Diamond continued carnival glass production at the Indiana site, often using molds and patterns developed during the Dugan period and introducing new ones, such as Peacock at the Fountain and Windflower. The plant maintained operations through World War I into the early years of the Great Depression.

Two catastrophic fires severely affected the Indiana glassworks: a 1912 blaze damaged molds and pattern stock, and another in June 1931 destroyed the plant’s main structures and inventory, leading to permanent closure. The property was later sold to what became Indiana University of Pennsylvania.

While other Pennsylvania glassmakers, such as Westmoreland Glass, also produced carnival glass, the Indiana plant remains distinctive for its early involvement in American carnival glass production and for the succession of companies that operated there.

Differences Between Carnival and Depression Glass

Carnival glass and Depression glass are often confused because both are molded household glasswares produced in large quantities during the early twentieth century. However, they differ in purpose, appearance, manufacturing techniques, and historical context.

| Feature | Carnival Glass | Depression Glass |

|---|---|---|

| Primary era | 1908–25 | 1929–39 |

| Surface finish | iridescent metallic sheen | no iridescence |

| Purpose | decorative, promotional | functional household wares |

| Color source | surface treatment | color in the glass itself |

| Typical patterns | ornate, raised designs | simpler, practical designs |

Carnival glass is best understood as decorative pressed glass with an applied iridescent finish, rooted in pre-World War I innovation. Depression glass, by contrast, reflects the economic realities of the 1930s, emphasizing affordability, utility, and mass distribution without surface ornamentation. While both are historically important, they serve fundamentally different roles in American material culture.

Carnival glass is best understood as decorative pressed glass with an applied iridescent finish, rooted in pre-World War I innovation. Depression glass, by contrast, reflects the economic realities of the 1930s, emphasizing affordability, utility, and mass distribution without surface ornamentation. While both are historically important, they serve fundamentally different roles in American material culture.

Carnival glass patterns varied widely by manufacturer and period, and there are hundreds of named patterns. Some patterns were associated with specific makers (e.g., Northwood, Fenton, Dugan), while others were used across companies.

Pattern names often reflect the visual motif (e.g., peacock, grape, floral, cable) or design structure (e.g., basketweave, hobstar).

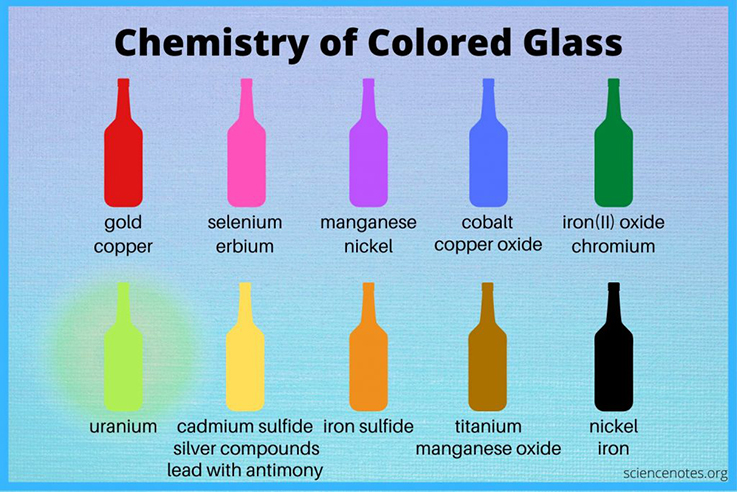

Many pieces were made in the common marigold color, but carnival glass also appears in green, violet, blue, amethyst, and other colors—with rarer colors typically commanding higher collector interest.

How Carnival Glass is Made

Carnival glass is made through a pressed-glass manufacturing process followed by the application of an iridescent surface treatment. The method allowed manufacturers to produce visually striking glassware efficiently and at low cost, making it widely accessible in the early twentieth century. The process can be summarized in several key stages.

- Glass Batch Preparation. Raw materials, including silica (sand), soda ash, lime, and colorants, are mixed and heated in a furnace to 2000°F until molten.

- Pressed Glass Forming. A measured amount of molten glass (called a gob) is dropped into a metal mold engraved with a decorative pattern and then pressed with a plunger to form the molten glass into shape. The molds could be used thousands of times.

- Rim Shaping and Finishing. The rims of carnival glass can be ruffled, crimped, or flared by hand tools to enhance their visual appeal. Excess glass is trimmed away, and the piece is smoothed as needed.

- Application of Iridescent Coating. The hallmark shimmering, “oil-slick” surface is the result of a metallic spraying process. While the glass is hot, it is sprayed with a solution of metal salts (e.g., tin, magnesium, iron, or bismuth compounds), which cause the salts to chemically bond to the glass surface and produce a thin iridescent layer.

- Annealing. After spraying, a long thermal rest in a special oven allows the glass to cool slowly over time. This annealing process prevents stress fractures, warping, or later failure.

Many carnival glass items were sold inexpensively or given away as promotional items, fair prizes, or premiums, contributing to the name “carnival glass.” Despite its low original cost, the visual complexity and durability have made many pieces highly collectible today.

The combination of pressed-glass molding and metallic iridescence allowed companies such as Northwood, Dugan, Diamond, and Fenton to produce decorative glass that mimicked expensive art glass while remaining affordable. This efficient, semi-industrial process is what made carnival glass one of the most widely produced and recognizable forms of decorative American glassware.

Carnival Glass Display in Kopchick Hall

Indiana native Arnold Wolfe is an avid carnival glass collector and member of the Rainbow Diamond Glass Club. He has graciously loaned a portion of his glass collection for display on the second floor of Kopchick Hall near the Oak Grove entrance. The display can be visited during the spring 2026 semester, 8:00 a.m.–8:00 p.m. Monday through Friday, as part of the John J. and Char Kopchick College of Natural Sciences and Mathematics’ Science on Display website.